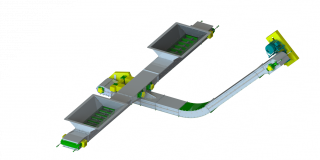

The Sukup grain bucket elevator is built for high-capacity, reliable grain movement in commercial and agricultural material handling systems. It is designed for gentle, low impact grain handling, helping preserve grain quality throughout the process.

Key features include UHMW shaft seals, heavy-duty rubber belting, and precision-welded trunking. The low profile discharge head reduces grain damage by allowing a smooth flow along the hood contour. This bucket elevator for grain is built to last and performs consistently in demanding operations.

Standard Features

- Up to 60,000 BPH capacity range

- Rubber belting works in all climates

- Patented alignment pins on squaring plates ensure a straight-on connection before leg sections are bolted together (U.S. Patent #8,668,079)

- Optional boot pulleys for various commodities

- Low profile head design for gentle discharge of grain

- Robot, fixture welded trunking for consistent square and parallel construction

- No. 3 vented buckets are standard

Boot Features

- Heavy structural frame

- Acme screw take-up

- Large clean-out doors

- Easy, tool-free access door

- Drip/rain guard to minimize water running into bottom of boot

- Smooth, crown-faced boot pulley

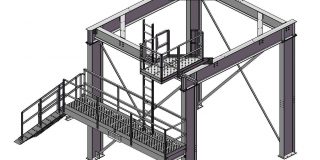

Head Features

- Large work platforms

- Split hood allows for easy interior accessibility without having to completely remove the hood

- Externally-mounted, heavy-duty pillow block roller bearings on head with easy adjustability with standard adjustment bolts

- Heavy-duty, crowned face, slide lagged head pulley

- Static conductive, oil resistant and fire retardant (SOFR) rubber belting standard

- Turned, ground and polished shaft

- Corrosion-resistant Acme thread take-up screws at boot

- High-density, non-sparking, polyethylene buckets

PRODUCT ACCESSORIES

- Liner packages available-urethane, high-energy urethane, ceramic, kryptane

- Optional gravity take-up

- Nylon, urethane, and steel buckets are optional when moving highly abrasive materials

- No. 4 vented buckets available

- Pressure relief door, standard on 36" and larger head section

- Winged pulley is a great option if you are concerned about material collecting on the pulley face

- Herringbone spiral winged pulley runs more quietly than a winged pulley

- Head service platform - One of the largest in the industry available in 3 different sizes

- Distributor platform available in 4'x8'

- Standard, flared, or 45 degree inlets available

- Explosion panels available, check local NFPA requirements

Product Features

- Low Impact Head Design for Better Grain Quality

- Squaring Plates for Efficient Assembly & Increased Strength

- Welded Frames on Head & Boot Sections

Dan Clark, Homeland Energy Solutions

Lawler, IA

I have to admit, we kind of raised our eyebrows on 'zero-entry' but once we got the sweep dialed in, it was truly flawless. I don’t have to babysit or keep a man there to watch it. [Sukup Zero-Entry Sweep]