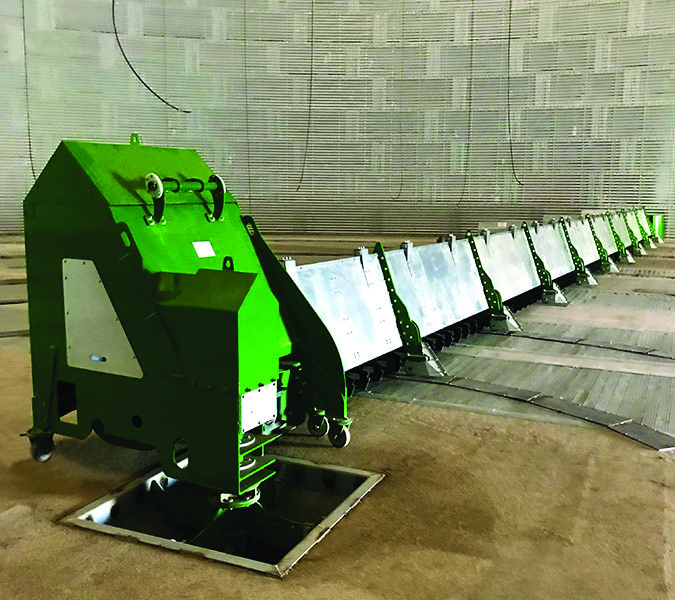

Sukup Zero-Entry Commercial Paddle Sweeps are designed to streamline grain handling operations while prioritizing safety, durability, and efficiency. With patented pivot point technology, these sweeps allow for "free-floating" adjustments to accommodate variations in concrete, ensuring consistent performance. The innovative A-shaped shield is designed to distribute grain loads better, enhancing durability and operational effectiveness.

Available in 5,000bu/hr and 10,000bu/hr capacities, these sweeps offer flexibility for various bin sizes and setups. The adjustable wall scraper and rubber-tipped scraper maximize the grain collected and minimize the amount of grain left between the sweep and bin wall. Powered by industrial-grade explosion-proof motors, the paddle sweeps are built to handle deep grain depths with greater safety and durability. With an automatic control box equipped with touchscreen functionality and programmable logic controls (PLC), operators can easily customize and monitor sweep performance for optimal results. Available as an option, the serrated UHMW paddles will break up any crusted layers while the rubber paddles almost completely clean the floor.

Key features like heavy-duty frames, foam-filled industrial pusher tires, and advanced safety mechanisms, including emergency stop buttons, ensure reliable and secure operation. Sukup's Zero-Entry Commercial Paddle Sweeps eliminate the need for personnel to enter the bin, offering a safer and more efficient grain handling solution.

Standard Features

- Heavy-Duty Zero-Entry Explosion-Proof Rotating Contact provides power to the sweep, there is no need to enter the bin

- Up to 10,000 BPH

- Patented pivot point allows the sweep to “free-float” to account for variations in concrete (U.S. Patent #9,327,921)

- Heavy-duty Frame designed to provide optimal strength to withstand the intense pressure of deep grain depths

- Heavy duty take-up bearings supply long lasting durability and strength

- Shallow Center Sump is cast in place and requires less concrete, saving you construction costs. Deeper design is also available

- Explosion-Proof Motors and industrial grade gear box and bearings for greater safety and durability

- Heavy-Duty Zero-Entry Explosion-Proof Rotating Contact provides power to the sweep. There is no need to enter the bin

- Emergency Stop Button for enhanced safety

- Zero-Entry Automatic Touch Screen Controls allow the pushers’ start and stop points to be user programmed on the touch screen to keep the paddles running efficiently based on a particular situation. In automatic mode, the controller senses chain load and advances the sweep without overloading the chain motor, preventing spinning of the pusher tires, which can cause extra wear. The sweep controls also have a manual mode that allows the operator to control sweep advancement.

- Programmable Logic Controller (PLC) provides greater reliability

- Industrial Grade Pushers are equipped with explosion-proof motors and foam-filled tires for safety and durability. Pusher speeds are based upon their location on the sweep through the use of varying gear ratios. This results in the pushers applying uniform pressure to the sweep, reducing wear on the inside pushers.

- Heavy-Duty Steel Wheels with bronze bushings

- Heavy-Duty Frame designed to provide optimal strength to withstand the intense pressure of deep grain depths

- Adjustable Rubber-Tipped Scraper behind the paddles maximizes the amount of grain collected along the bin floor

Product Features

- Heavy-Duty frame

- Industrial grade pushers

- Patented pivot point

Maumee, OH